The OTC Brasil Spotlight on New Technology Awards Program is designed to recognize technologies that have pushed the boundaries and provided value in unimaginable ways to the future of offshore activities. This award program is exclusively for OTC Brasil exhibitors and showcases the latest and most advanced technologies that are leading the industry into the future.

REQUIREMENTS

To be considered, the technology must meet six key criteria and the company must be an exhibitor at OTC Brasil.

- New. The technology must have been offered to the marketplace in a ready-for-commercialization state less than two years prior to the application date.

- Innovative. The technology must be original, groundbreaking, and capable of having a major impact on the offshore E&P industry.

- Ready. A proposed type of equipment must meet the requirements of API 17Q Technology Readiness Level of TRL4 or higher to qualify for submission.

- Broad Interest. The technology must interest and appeal to the industry.

- Significant Impact. The technology must provide significant benefits exceeding existing

- Regional Impact. The technology must provide significant benefits to the region.

WINNING TECHNOLOGIES RECEIVE

- Acknowledgment in an OTC Brasil press release.

- Advanced recognition on the OTC Brasil website and on OTC Brasil social media platforms.

- Acknowledgment at an on-site awards ceremony with press invited.

- Recognition in a special section of the digital OTC digital and/or printed conference program.

- Designation on the exhibit floor with a customized Spotlight on New Technology banner.

- Use of the Spotlight on New Technology logo.

- Recognition as a Spotlight on New Technology winner at any of the OTC events that are held within 11 months of the OTC of which they won.

SMALL BUSINESS AWARD

OTC Spotlight on New Technology Small Business Award recipients will receive the same benefits as listed above, with the added recognition as a "Small Business Award" recipient. The Spotlight on New Technology Small Business Award® recognizes the innovative technologies being developed by small businesses (less than 300 employees). To be considered, your company must :

-

Be independently owned and operated or a not-for-profit concern.

-

Have no more than 300 employees for the preceding 12 months.

-

Meet all other Spotlight on New Technology award program requirements.

Congratulations to the

2023 Spotlight on New Technology® Award Winners

Bosch Rexroth – Lean All-Electric Subsea Valve Actuation based on SVA R2

SVA R2 is the world’s first lean all-electric actuator to replace hydraulic actuators with field-proven safety technology. It is ready for use in subsea production and process systems, building the basis for an all-electric actuation portfolio to accelerate the energy transition industry such as carbon storage and green hydrogen production.

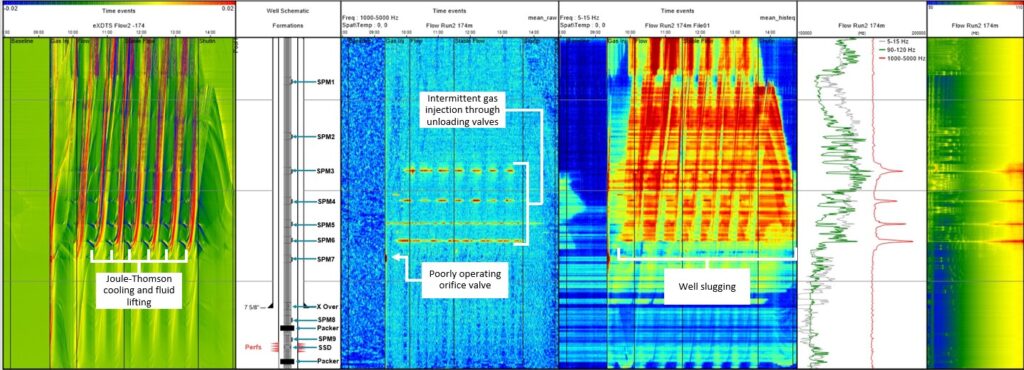

Expro – HotDAS, ExDTS and QikView DFOS Data Processing and Visualization Software

Expro’s Distributed Fiber Optic Sensing (DFOS) processing and visualization software provides user friendly rapid access to information eliminating the “big data “ problem at source. It enables integration with other well data within hours of DFOS acquisition driving quality decision making and interpretation leading to robust remediation and intervention.

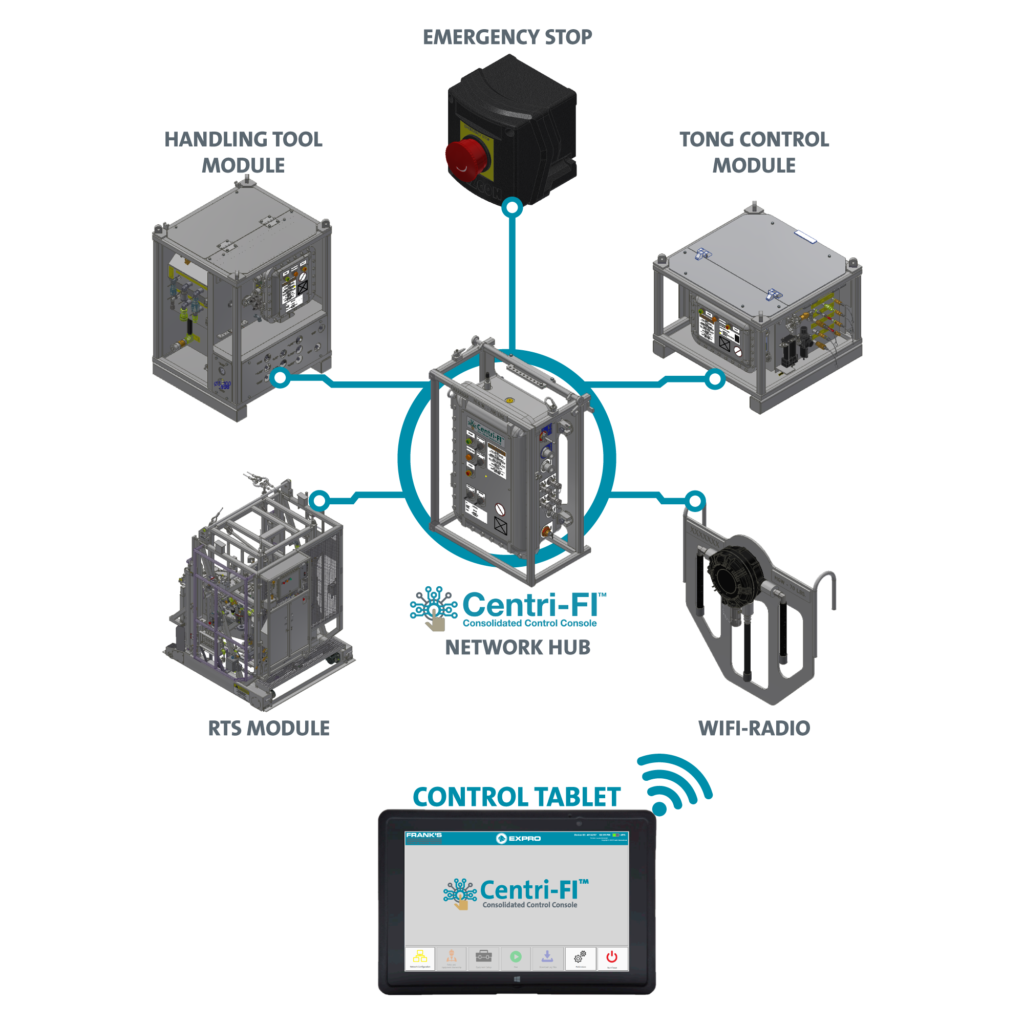

Expro – Centri-FI™ Consolidated Control Console

Expro’s Centri-FI™ Consolidated Control Console provides a hands-free solution for a single operator on multiple tubular running service tools through a single-push button tablet interface allowing fully remote operations and equipment status visibility to drillers and supervisors through automation, mechanical intelligence, and a digital system with safety interlocks.

DeltaTek, an Expro Company – QuikCure®

QuikCure®, which utilizes Deltatek’s SeaCure® inner-string technology as an installed conduit, is the engineered process of circulating heated fluid after cement slurry placement to elevate the surrounding cement setting environment. QuikCure® has proven to reduce wait on cement by approximately 70%, resulting in a more efficient, reduced-risk, zonal isolation operation.